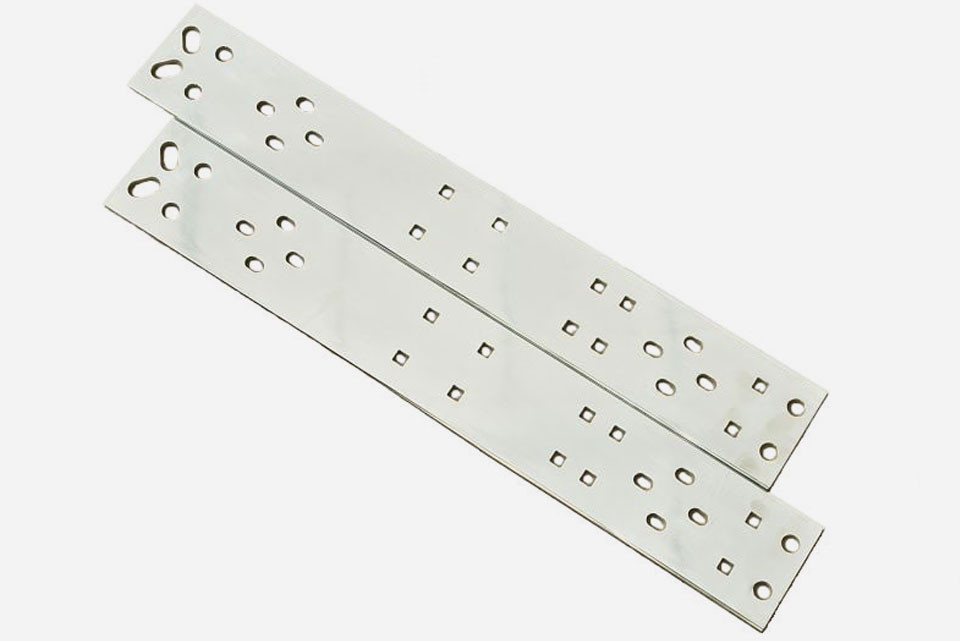

Our modern device, created based on advanced water jet technology, employs an abrasive-containing water jet which, when ejected at a very high pressure, allows a wide range of materials to be cut and processed.

Water cutting

Parameters of our device:

- work table 2000 x 4000 mm

- max. pressure 4000 bar

- CNC positioning /- 0.1 mm

- thickness of the materials cut of up to 150 mm

- the accuracy of the shapes cut out depends on the material thickness and type

- CAD software featuring the material sheet cutting optimisation function

In contrast to laser or plasma cutting technology, water jet cutting technology eliminates the risk of high temperature and chemical agents which have an impact on the material being processed. This is one of the main advantages of this material processing method, thanks to which we can cut lacquered or electroplated materials – as well as acid-resistant steel – without discolouration.

Water cutting

We provide cutting services for

- non-ferrous metals and their alloys

- structural steel, stainless steel, tool steel, alloy steel

- plastics

The main advantage of this material processing method is the low temperature of cutting, thanks to which we can cut lacquered or electroplated materials – as well as acid-resistant steel – without discolouration.

Another important advantage of water jet cutting technology is the short production preparation process which, when combined with the CNC software, makes it possible to use this method for both individual piece production and macro-scale production.

Based on the files sent, we will prepare an individual quotation for you, ensuring a fast completion date, free design preparation and the possibility of transport.

Water jet cutting

…

Water jet cutting

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Vivamus gravida rhoncus fermentum. Nunc con…

Water jet cutting

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Vivamus gravida rhoncus fermentum. Nunc con…

Water jet cutting

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Vivamus gravida rhoncus fermentum. Nunc con…

Water cutting

See our machinery stock